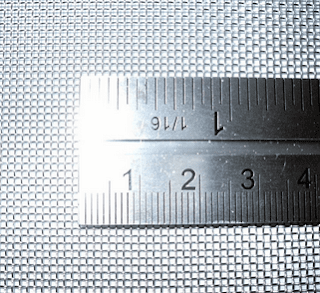

Screen Mesh Size Chart . Please be rest assured that we can customize it as your requirement. As the number describing the mesh.

Stainless Steel Micron Rating Examples - Utah Biodiesel Supply Blog from www.utahbiodieselsupply.com

Higher mesh numbers = smaller particle sizes. Mesh size tells you how many openings there are in an inch, which can be calculated to provide you with the same information. % oa mesh mesh 14 16 20 44 48 58 60 64 80 84 88 90 105 120 145 165 200 230 300 76.

Stainless Steel Micron Rating Examples - Utah Biodiesel Supply Blog

% oa mesh mesh 14 16 20 44 48 58 60 64 80 84 88 90 105 120 145 165 200 230 300 76. All you do is count the number of openings in one inch of screen (in the united states, anyway.) the number of openings is the mesh size. The weave type is plain or twill. Particle size to screen mesh conversion chart.

Source: www.industrialspec.com

The size of the mesh has a lot to do with how detailed your image is and how thick the ink you are using is. % oa mesh mesh 14 16 20 44 48 58 60 64 80 84 88 90 105 120 145 165 200 230 300 76. As the number describing the mesh. The weave type is plain.

Source: www.pharmaguideline.com

Mesh size is not a precise measurement of particle size. Particle size to screen mesh conversion chart tensile bolting cloth mill grade market grade clear opening u.s. It is very important to remember that mesh size is not a precise measurement of the mesh opening size. It is the number of openings in one inch of screen. Higher mesh screens,.

Source: www.e-fab.com

Higher mesh screens, 200 mesh and above, are most often used for finer detail images and thinner inks. Figuring out mesh sizes is simple. As the number indicating the mesh size increases, the size of the openings and thus the size of particles captured by the screen decreases. Sieve mill grade % % % closest opening % inches microns mesh.

Source: www.wirecloth.com

Higher mesh screens, 200 mesh and above, are most often used for finer detail images and thinner inks. As the number describing the mesh. % oa mesh mesh 14 16 20 44 48 58 60 64 80 84 88 90 105 120 145 165 200 230 300 76. This can easily be determined as screens are made from wires of.

Source: www.utahbiodieselsupply.com

Magnacolours® technical data sheets will list the mesh counts suitable for use in both of these formats. The higher mesh count helps to keep the thinner inks from flooding onto your substrate. Mesh size tells you how many openings there are in an inch, which can be calculated to provide you with the same information. Higher mesh numbers = smaller.

Source: www.haochengwiremesh.com

Count the number of openings in one inch of screen (united states mesh size). .9 47.3 47.1 45.2 45.0 40.5 2 10 12 16 18 20 22 24 26 28 32 36 40 45 50 55 60 79.6 76.7 74.0 70.6 69.6 64.8 62.7. As the number indicating the mesh size increases, the size of the openings and thus the.

Source: www.wateropolis.com

As the number indicating the mesh size increases, the size of the openings and thus the size of particles captured by the screen decreases. Mesh size is measured by how many threads of mesh there are crossing per square inch. As the mesh size increases, the particle size decreases for finer material. Higher mesh screens, 200 mesh and above, are.

Source: www.911metallurgist.com

% oa mesh mesh 14 16 20 44 48 58 60 64 80 84 88 90 105 120 145 165 200 230 300 76. .9 47.3 47.1 45.2 45.0 40.5 2 10 12 16 18 20 22 24 26 28 32 36 40 45 50 55 60 79.6 76.7 74.0 70.6 69.6 64.8 62.7. 4 64.8 62.7 60.7 5b. The.

Source: murakamiscreen.com

The number of openings is the mesh size. We’ve put together this handy table below to help you with more size conversions. Figuring out mesh sizes is simple. As the number indicating the mesh size increases, the size of the openings and thus the size of particles captured by the screen decreases. Mesh size is measured by how many threads.

Source: www.commercialfiltrationsupply.com

.9 47.3 47.1 45.2 45.0 40.5 2 10 12 16 18 20 22 24 26 28 32 36 40 45 50 55 60 79.6 76.7 74.0 70.6 69.6 64.8 62.7. For instance, a 110 mesh screen has 110 threads crossing per square inch. % oa mesh mesh 14 16 20 44 48 58 60 64 80 84 88 90 105.

Source: utahbiodieselsupply.com

As the number describing the mesh. The us size refers to the number of threads per inch. 39 rows the chart below shows the approximate size in inches and microns for various mesh. What does mesh size mean? Higher mesh numbers = smaller particle sizes.

Source: www.researchgate.net

Particle size to screen mesh conversion chart. Mesh size tells you how many openings there are in an inch, which can be calculated to provide you with the same information. The higher mesh count helps to keep the thinner inks from flooding onto your substrate. Please kindly check the following stainless steel wire screen mesh size chart. The higher the.

Source: shakerscreens.org

If you don’t find the mesh you need in the below woven wire mesh sizes chart, don’t worry about it. It is very important to remember that mesh size is not a precise measurement of the mesh opening size. The higher mesh count helps to keep the thinner inks from flooding onto your substrate. As the mesh size increases, the.

Source: www.preferredprocesssolutions.com

The higher the mesh count, the finer the threads and holes are in the screen. If you don’t find the mesh you need in the below woven wire mesh sizes chart, don’t worry about it. % oa mesh mesh 14 16 20 44 48 58 60 64 80 84 88 90 105 120 145 165 200 230 300 76. Mesh.

Source: www.kmizeolite.com

The higher the mesh count, the finer the threads and holes are in the screen. It is very important to remember that mesh size is not a precise measurement of the mesh opening size. All you do is count the number of openings in one inch of screen (in the united states, anyway.) the number of openings is the mesh.

Source: www.haochengwiremesh.com

Please kindly check the following stainless steel wire screen mesh size chart. .9 47.3 47.1 45.2 45.0 40.5 2 10 12 16 18 20 22 24 26 28 32 36 40 45 50 55 60 79.6 76.7 74.0 70.6 69.6 64.8 62.7. It is very important to remember that mesh size is not a precise measurement of the mesh opening.

Source: www.macrokun.com

The higher the mesh count, the finer the threads and holes are in the screen. Below is a conversion chart to give you an idea of how micron and mesh relate to each other. We’ve put together this handy table below to help you with more size conversions. 7 56.7 8 59.1 57.4 8 2 52.6 51 49.4 54. All.

Source: elcanindustries.com

.9 47.3 47.1 45.2 45.0 40.5 2 10 12 16 18 20 22 24 26 28 32 36 40 45 50 55 60 79.6 76.7 74.0 70.6 69.6 64.8 62.7. As the number describing the mesh. All you do is count the number of openings in one inch of screen (in the united states, anyway.) the number of openings is.

Source: www.tatasteelsmartfab.com

Figuring out mesh sizes is simple. Screen printing mesh size chart Particle size tensile bolt cloth market grade clear opening u.s. It is the number of openings in one inch of screen. The mesh number system is a measure of how many openings there are per linear inch in a screen.

Source: www.pharmaguideline.com

Below is a conversion chart to give you an idea of how micron and mesh relate to each other. The mesh number system is a measure of how many openings there are per linear inch in a screen. Please kindly check the following stainless steel wire screen mesh size chart. It is very important to remember that mesh size is.