Piston Ring Gap Chart . File fit ring sets require filing of the top and 2nd rings to achieve the correct end gap. Piston rings lead the industry for the latest in piston ring technology.

Piston Ring Gap | The Late Bay from thelatebay.com

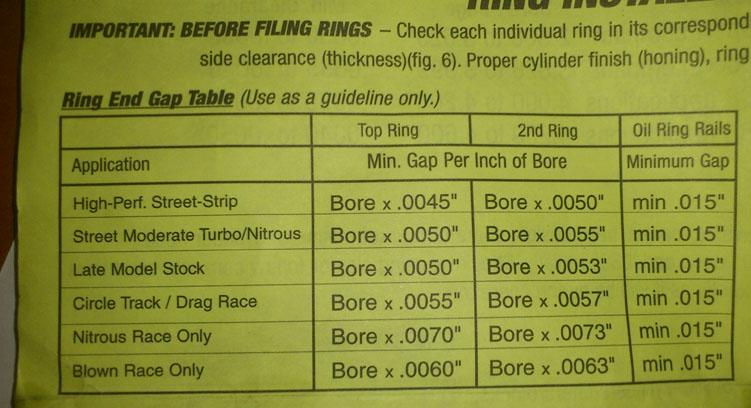

To find the proper ring end gap, multiply your bore size by the ring end gap factor listed on the chart (i.e., street naturally aspirated 4.000” bore x.0065” gap. These are based on different user applications. Ring gap table instructions 1.

Piston Ring Gap | The Late Bay

In seeking for the optimum end gap for your particular engine, choose the proper application in the chart and gap the rings to the high limit. Piston rings lead the industry for the latest in piston ring technology. When you shop for high performance piston ring sets, you’ll no doubt find there are many different sets and styles available (no big secret). So for a 4 inch bore, the standard end gap would be.016 inches.

Source: www.cp-carrillo.com

The broken piece may cause further piston or engine damage. This can directly bleed off the precious cylinder pressure that is so difficult to achieve. Ring gap table instructions 1. Piston rings should be file fitted to the desired end gap with the torquing plate attached. It stands to reason that a large gap at the end of the ring.

Source: blog.wiseco.com

To properly measure the ring gap, the ring should be square in the bore 1” down from the deck. Modern piston design locates the top ring higher for improved requires a larger top ring end gap. Cylinder should be free of any taper. Different applications require different amounts of gap. Adjusting your ring end gaps is done with a piston.

Source: www.mgexp.com

Use the piston to square up the ring in the bore, and check the end gap by using a feeler gage. Modern piston design locates the top ring higher for improved requires a larger top ring end gap. Most piston ring manufacturers recommend a minimum end gap of.004 inches times the bore diameter for the top piston compression ring. These.

Source: www.evolutionm.net

Please follow the gapping chart supplied with the ring set. For the 2nd compression ring, the standard end gap recommendation for most stock engines is typically.005 in. .015 min 2nd bore bore bore bore bore bore bore bore bore bore 2nd bore bore bore bore bore bore bore bore bore bore ring.0045 x.0055 x 0065 x. See table below for.

Source: www.evolutionm.net

Never use oem ring end gap specs, as the material and applications are wildly different. Gap adjustments to the top and second rings. Please follow the gapping chart supplied with the ring set. If running aggressive boost or nitrous applications it may be necessary to increase end gaps. Current racing engines put a greater demand on piston rings than ever.

Source: pages.facebook.com

Total seal recommended gap chart all except gapless top oil rail 015 min. In worn cylinders, make sure that ring gaps are checked at bottom of ring travel. To find the proper ring end gap, multiply your bore size by the ring end gap factor listed on the chart (i.e., street naturally aspirated 4.000” bore x.0065” gap. Piston rings lead.

Source: thelatebay.com

The gap should be a minimum of.010”. So for a 4 inch bore, the standard end gap would be.016 inches. Adjusting your ring end gaps is done with a piston ring file and there are two options when it comes to this — manual or electric. The second ring end gap would be 4.000 x.0045″ =.018″. Use the chart below.

Source: www.hpacademy.com

Follow the ring gap instructions for the pistons you are using. Safe top ring end gaps can be found by multiplying the bore diameter by the appropriate ring end gap factor from the clearance chart. Modern piston design locates the top ring higher for improved requires a larger top ring end gap. Multiply bore size x ring end gap factor..

Source: www.golfmk7.com

This allows you to set the ring gap precisely to your exact needs. Safe top ring end gaps can be found by multiplying the bore diameter by the appropriate ring end gap factor from the clearance chart. It stands to reason that a large gap at the end of the ring makes for an easier leak path. Modern piston design.

Source: www.svtperformance.com

Different applications require different amounts of gap. For the 2nd compression ring, the standard end gap recommendation for most stock engines is typically.005 in. Multiply bore size x ring end gap factor. To find the proper ring end gap, multiply your bore size by the ring end gap factor listed on the chart (i.e., street naturally aspirated 4.000” bore x.0065”.

Source: www.mgexp.com

Measure the ring end gap with a feeler gauge or equivalent device. This allows you to set the ring gap precisely to your exact needs. The gap should be a minimum of.010”. To find the proper ring end gap, multiply your bore size by the ring end gap factor listed on the chart (i.e., street naturally aspirated 4.000” bore x.0065”.

Source: www.aa1car.com

Piston rings should be file fitted to the desired end gap with the torquing plate attached. All of these factors have created a need for a piston ring that’s stronger, lighter, seals better, For the 2nd compression ring, the standard end gap recommendation for most stock engines is typically.005 in. Most piston ring manufacturers recommend a minimum end gap of.004.

Source: www.mr2.com

See table below for proper ring end gap for your application. To find the proper ring end gap, multiply your bore size by the ring end gap factor listed on the chart (i.e., street naturally aspirated 4.000” bore x.0065” gap. Total seal recommended gap chart all except gapless top oil rail 015 min. The gap should be a minimum of.010”..

Source: blog.diamondracing.net

These are based on different user applications. The oil rails should always have a. Different applications require different amounts of gap. To find the proper ring end gap, multiply your bore size by the ring end gap factor listed on the chart (i.e., street naturally aspirated 4.000” bore x.0065” gap. If for some reason the gapping chart is missing or.

Source: www.enginelabs.com

Cylinder should be free of any taper. This allows you to set the ring gap precisely to your exact needs. To find the proper ring end gap, multiply your bore size by the ring end gap factor listed on the chart (i.e., street naturally aspirated 4.000” bore x.0065” gap. Gap adjustments to the top and second rings. Measure the ring.

Source: www.aa1car.com

Please follow the gapping chart supplied with the ring set. Use this chart to determine the proper end gap for your engine. Use the chart below to determine the minimum ring end gap. Cylinder should be free of any taper. Calculate the recommended ring end gap from the chart above.

Source: www.enginebuildermag.com

Gap adjustments to the top and second rings. Maximum ring gap is an important part of ring performance in that too much gap results in lost compression, power loss, and ultimately poor oil control. This can directly bleed off the precious cylinder pressure that is so difficult to achieve. Multiply bore size x ring end gap factor. This allows you.

Source: powerjdm.com

Please follow the gapping chart supplied with the ring set. The oil rails should always have a. Gap adjustments to the top and second rings. Modern piston design locates the top ring higher for improved requires a larger top ring end gap. Piston rings lead the industry for the latest in piston ring technology.

Source: procycle.us

Use the piston to square up the ring in the bore, and check the end gap by using a feeler gage. Piston rings should be file fitted to the desired end gap with the torquing plate attached. Failure to provide sufficient top ring end gap will cause a portion of the top ring land to break as the ring ends.

Source: auto.jepistons.com

Ring end gap should be measured with the ring square in the bore on a fresh hone. Current racing engines put a greater demand on piston rings than ever before by running at higher operating temperatures, higher cylinder pressures, and higher operating rpm. The gap should be a minimum of.010”. Never use oem ring end gap specs, as the material.